Offset printing in Indore is the most commonly utilized procedures for creating marketing and promotional materials. The flexibility of this printing strategy is unmatched in the industry.

Offset printing is the most popular type of printing used nowadays. The offset printing in Indore, (M.P.) is common to the point that very nearly 40 % of the printing jobs are finished by the use of offset printing. The presences of offset printing work in Indore, is nearly felt in each industry.

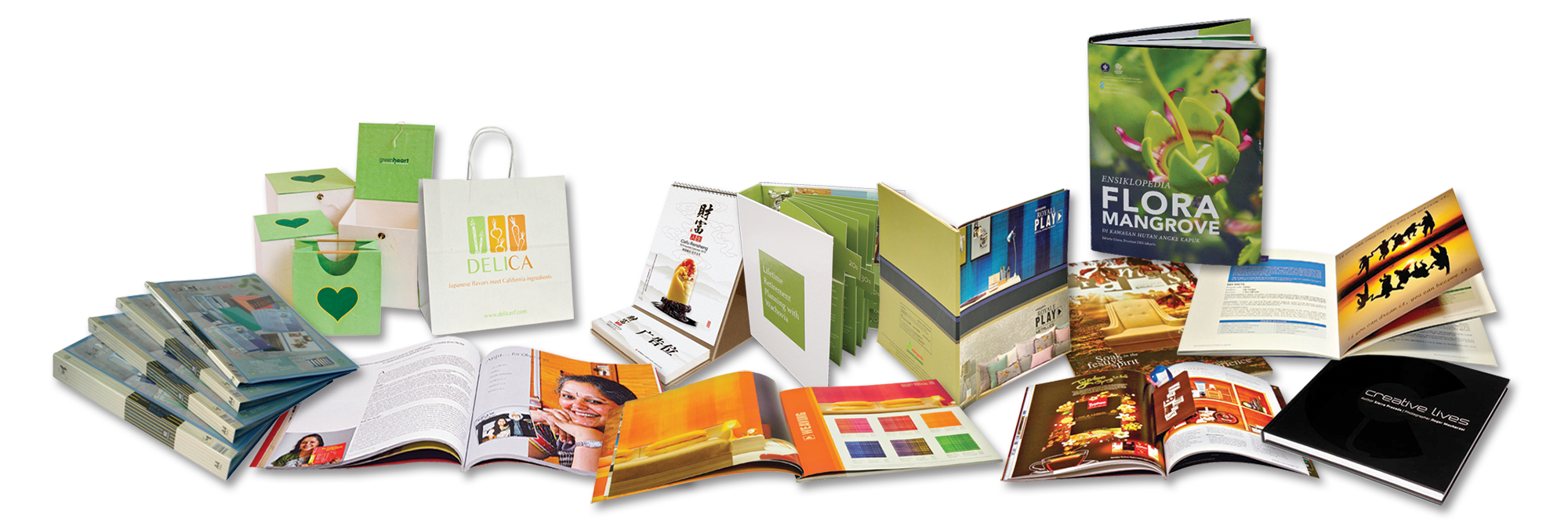

Offset printing in Indore, (M.P.) is an important way to advertise your business. Through this, you can get a boundless source of potential outcomes with the goal for you to expand your deals. Utilize the different print products and services available to attract customers and keep them.

Offset printing, also called lithographic printing, uses the four essential colors, the CMYK or cyan, magenta, yellow and black.